How can I implement EDI – Electronic Data Interchange – in my company ?

19 June 2023

19 June 2023

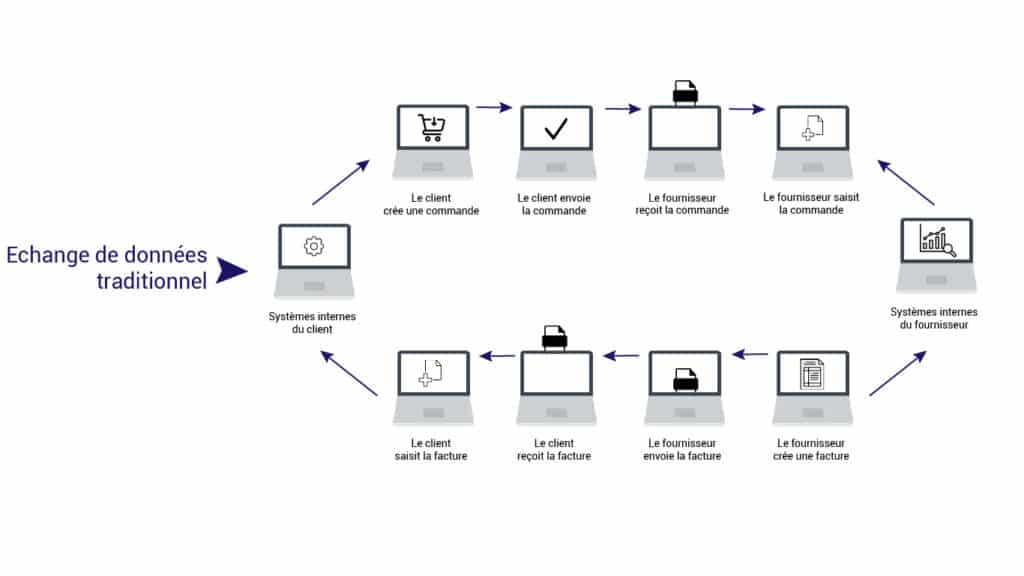

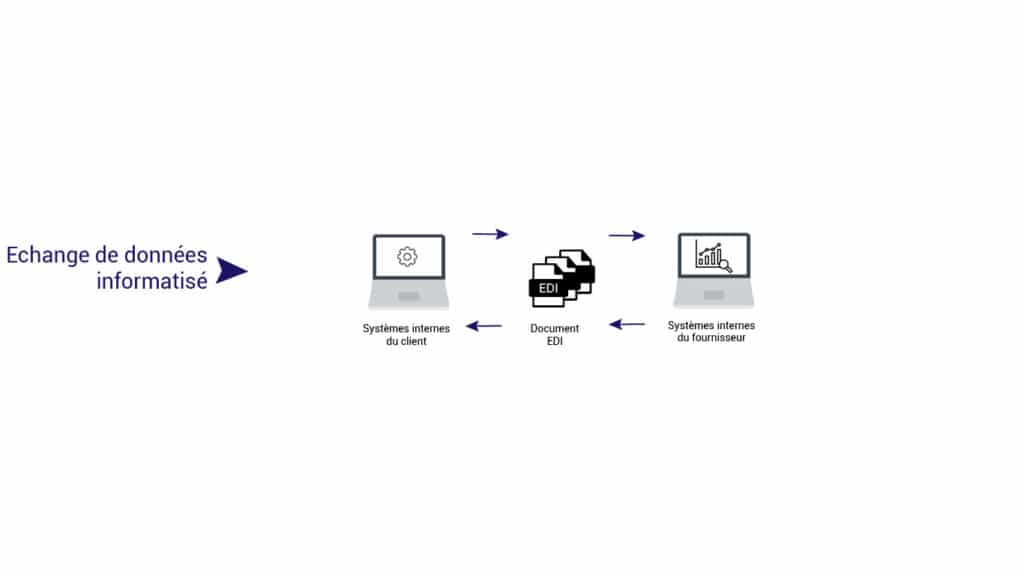

Implementing EDI means carrying out a cross-functional supply chain project; integrating EDI (Electronic Data Interchange) into the company has an impact on its relations with its network of commercial partners. It also impacts internal exchanges between different departments. By dematerializing exchanges, EDI contributes to the digital transformation of the company’s businesses.

Implementing EDI (Electronic Data Interchange) in a company means automating commercial relations between companies (partners), and eliminating unnecessary and redundant data entry.

The aim of this change is to accelerate and secure the commercial exchange cycle, and to achieve productivity gains and reductions in administrative costs.

This evolution impacts commercial relations with business partners, customers and suppliers. It also contributes to the company’s digital transformation by eliminating paper and automating business processes.

Find out in this article how to implement EDI, and what action plan to put in place. We will also

we detail the various stages involved in successfully implementing EDI in your company.

Whether you are the initiator of an EDI project, and want your trading partner network to buy into it as much as possible. Whether you are carrying out an EDI project to meet the demands of your trading partners and join their EDI networks. You approach your EDI project from two angles: “Technical” and “Organizational”.

Implementing Electronic Data Interchange is a much larger project than most IT projects.

Setting up an EDI system not only involves enabling separate computer systems to exchange electronic messages with each other, it also involves :

We will now look at how to implement EDI along two distinct axes :

To achieve this, it will need to be made up of members from each of the company’s departments and its management. Its role will be not only to manage the technical aspects of the EDI project, but also to anticipate changes in the internal organization of departmental work. It will also have to communicate with future EDI partners.

First of all, analyze your needs, identify the EDI flows to be implemented and their volumes. Then choose the most suitable EDI solution and its EDI VAN network. Then integrate the software into the EDI system, prepare the data and start testing.

This step will enable you to list exhaustively :

This inventory will make it possible to estimate the volume of exchanges when EDI goes into production.

Once the requirements have been assessed, the Steering Committee has all the information it needs to :

The choice of EDI provider will be based on pricing criteria, taking into account forecast volumes and the quality of services offered and guaranteed by the EDI provider.

The software used by the company to interface with the EDI gateway – accounting, ERP, sales management, TMS, WMS, etc. – will have to be made communicative if this is not already the case. This will require either updates with EDI modules, or specific developments.

Once the EDI solution has been chosen, the software to be integrated will be connected to EDI. All that remains to be done is to prepare the data to be exchanged.

Data preparation is essential for EDI implementation. This operation consists of :

EDI standardization organizations such as GS1, Galia and GTF help companies bring their data up to standard. They also provide extensive documentation.

This is a critical operation in the project process. If the data in the company’s software is incorrect, incomplete or badly formatted, messages sent or received will be rejected.

Message transmission and reception tests must be carried out with each EDI partner. The tests involve all three parties: sender, receiver and EDI supplier.

Test sets based on real documents representing the various possible scenarios are created. These documents are then transmitted by EDI messages to the partners, who in turn confirm that they have received them and can process them. Once all tests have been successfully completed, the system can be put into production.

Informing and training : an EDI project is a step in the company’s digital transformation, which will have an impact on the company’s value chain. Good external and internal communication will help to win everyone’s support for the project.

The implementation of an Electronic Data Interchange (EDI) system will bring about changes in the way a company works :

As with all projects having an impact on the work of departments, it is necessary to organize meetings to present an EDI project that :

It will of course be necessary to provide user training so that they can take ownership of EDI and become autonomous in managing EDI deployment to new trading partners and handling anomalies.

It’s also a good idea to set up indicators to measure the performance of the EDI system vs. the pre-EDI situation: number of disputes, service rate, reduction in delivery times, number of paper printouts, etc.

The aim is to convince as many customers and suppliers as possible to join the company’s EDI network.

Setting up a new EDI connection requires the future EDI partner (customer or supplier) either to invest in EDI by carrying out an EDI project of their own, or at best to spend time setting up and testing the system.

To get them on board, I have to guarantee that my EDI system is reliable and operational:

The signing of an EDI or interchange contract with each partner with whom the company will be exchanging data electronically is an essential part of the business relationship. This agreement formalizes the means and terms of exchange between partners. Here is a non-exhaustive list: types of messages, protocols used, networks used, frequency of exchanges, contingency plan in case of malfunction, names of EDI managers for each signatory, etc.

Anticipate long lead times and the risk of poor-quality data.

Once testing has been successfully completed, it’s important to move quickly into production. Testing has guaranteed the quality of the information exchanged, and the smooth operation of integration into information systems. If there is too long a delay between the end of testing and the start of production, there is a significant risk of data quality deterioration due to modifications (creation, modification, deletion) made independently, without taking EDI into account.

Data that is too frequently of poor quality will lead to frequent rejections and jeopardize EDI exchanges, risking customer or supplier dissatisfaction: penalties, loss of business.

Software solutions such as ETL (Extract Load Transform) or EAI (Enterprise Application Integration) enable an organization to manipulate and transfer data while guaranteeing its quality and formatting.

The objectives for message exchange volumes have been achieved, and the EDI system is up and running. The time has come to envisage new stages.

With the majority of business transactions now carried out electronically, companies will be able to take their business processes further, digitizing them and exchanging data and information electronically.

A WEBEDI service connected to the company’s EDI system, open to all to all:

Implementing EDI will open up new horizons for the company, enabling it to digitize and increase its commercial activity.

If you liked this article, don’t hesitate to consult this excellent article on the EDIFACT standard or EDI in the retail sector. Tenor has been helping companies implement Electronic Data Interchange for over 30 years. Discover our EDI software solutions and services.